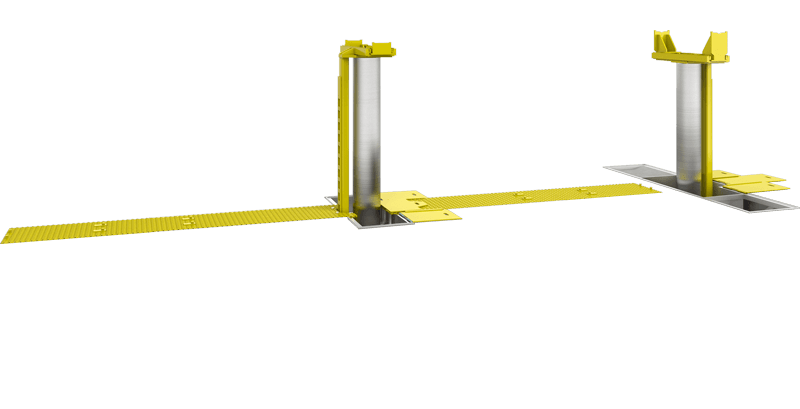

Depending on the model of choice, these lifts usually consist of two or three In-Ground hydraulic lifting pistons installed in a modular or continuous trench in a direct line with one other and are consistent with a vehicle’s central axis. Each plunger is hydraulically driven, using a very large motor and a series of pumps to displace a high volume of oil within the casing structure itself. The posts are equipped to safely engage a vehicle’s lifting points with the use of a variety of adapters. Depending on the model the front and center lifting pistons are capable of moving along the same axis to create the appropriate space needed for any vehicle to be situated onto its lifting points. The pistons move using a twin chain, pneumatically driven Z-drive. The rear lifting cylinder is fixed and non-movable with a retractable saddle or adapter.

Main features of these lifts include:

- PLC Controlled & Hydraulically Operated

- 10 5/8″ Chrome Plated Pistons

- Multi-position Safety locking legs with automatic air latch system

- One Large Motor running multiple pumps feeding each plunger

- Double chain hydraulic spotting system

- Front/Center frames made from 7/8″ thick forklift mast channel

- Adjustable pickup adapters

- 3/8″ Thick cover plates (retractable covers optional)

- Fiberglass coated piston casings. (optional)

- Low profile saddle (front and center recessed – optional)

- Pendant Control (optional)

Recent Comments